International Customs Airport Lobby: Fire Rated Stainless Steel Doors & Frame

Airport Terminal Pedestrian Access: Stainless Steel Doors & Frames

Stainless Steel

Stainless steel doors provide exceptional durability, corrosion resistance, and low maintenance to any door opening. They offer many years of trouble-free service.

Stainless steel doors and frames combine corrosion protection with outstanding design and beauty. A complete range of fire rated and non-fire rated products are available, making use of a wide variety of stainless steels.

Whether for beauty or functionality, stainless steel doors and frames serve a specific function whether it be pools, labratories or processing plants. However, the beauty of the product can often be seen in luxury apartments, hotels, offices, and residences across the globe.

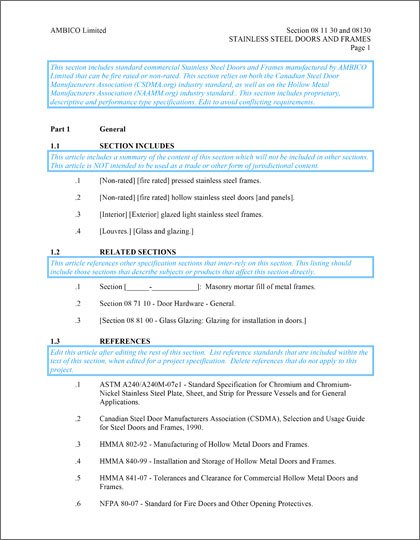

- Specifications

- Downloads

STAINLESS STEEL DOORS

- 12-18 gauge, 304 or 316 stainless steel slabs and frames available

- 45, 60, 90. and 180 minute fire-rating available

- Coloured stainless steel options in satin or mirror finish

- Satin finish (#4) is used in a wide variety of architectural and manufacturing environments

- Mirror finish (#8) is used when an outstanding polished finish is the primary objective

- Mill finish (#2B) is used in industrial applications where corrosion resistance is a primary concern

- Coloured stainless steels are available in satin and mirror finishes

- Products are available in a range of stainless alloys including #304 and #316.

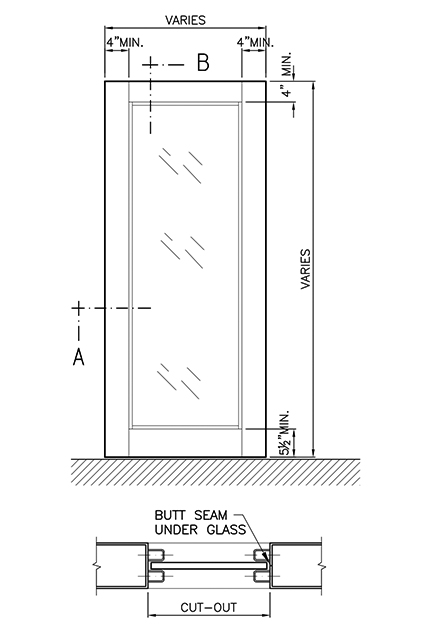

Door Size: Up to 4'0" in width x 8'0" in height. Available in single or double door openings.

Material: 16 or 18 Gauge 304 or 316 Stainless Steel.

Finishing: Available with the beauty of 304 or the utility of 316 Stainless Steel in either #4 brushed finish or 2B mill finish.

Fire Labelling: Available labelled from 45 minutes to 3 hours.

Available Frames: 14 or 16 Gauge Stainless Steel with finish to match door preparation. Minimum 3-1/2" throat and 4-1/2" jamb depth for either masonry or drywall applications.

Transom Panel: 1-1/2 hour fire rated Transom Panels up to 8'0" in width and 3'0" in height. The transom panel design is available as either fixed or removable and as either flat bottomed with astragal or rabbeted without astragal. The removable panel design can incorporate a slide-on-type panel fixed in place with labelled flushbolts. Removal is only a matter of holding the panel in place wile disengaging the flushbolts as you would with a pair of doors and sliding the panel off the rails. The panel can be restored by simply sliding the panel in place and sliding the flushbolts to their fixed position. This makes removing the panel very quick and convenient as no tools are required. Labelled surface bolts are an accepted alternative.

Features:

- Stock stainless steel doors and frames are ready for immediate shipment.

- Fire labelled products have been certified by Underwriters Laboratories and Warnock Hersey International.

- Fire labelled products may be supplied in singles or in pairs.

- Satin finish (#4) is used in a wide variety of architectural and manufacturing environments.

- Mirror finish (#8) is used when an outstanding polished finish is the primary objective.

- Mill finish (#2B) is used in industrial applications where corrosion resistance is a primary concern.

- Coloured stainless steels are available in satin and mirror finishes.

- Products are available in a range of stainless alloys including #304 and #316.

Warranty: Manufacturer's limited warranty – five (5) years from date of supply, covering material and workmanship.

Frequently Asked Questions

What is stainless steel? Stainless steel is defined as a series of steel alloys which include at least 10% chromium. Dozens of stainless steel alloys exist. By far the most common alloy used in door production is #304 which is composed of 18% chromium and 8% nickel. The #316 alloy is used with success in highly chlorinated environments such as public swimming pools or pulp mills and is composed of 16% chromium, 10% nickel, and 3% molybdenum. Contact Penner Doors & Hardware in order to help you to select the stainless alloy most appropriate to your project.

What finishes can be applied to stainless steel? Three common finishes can be applied to stainless steel alloys. The #2B "mill finish" is an unpolished and hence less expensive product suitable for use in corrosive environments where appearance is unimportant such as industrial applications. The #4 "satin finish" is the most common type of polish suitable for use in a broad variety of applications. This finish is also known as a "32D finish". The #8 "mirror finish" is suitable for highly decorative environments. This finish is also known architecturally as a "32 finish".

As well, a range of colored stainless steels are available. The colors include a deep blue, a dark bronze, and bright brass. These colors are chemically bonded to the stainless steel and maintain their color for the life of the product. They are available in mirror or satin finishes.

Penner Doors & Hardware also offers a variety of patterned finishes which can be embossed, etched or applied to the stainless steel. Send us a drawing, template or physical sample so we can match your unique finish requirements.

Can stainless steel doors and door frames be fire rated? The fire rating capabilities of a particular manufacturer are limited to those products that have been laboratory tested by that firm. Our manufacturers' capabilities in the field of fire rated stainless steel doors and frames are the broadest in the industry. They include single door/door frame units rated to 3 hours. As well they include pairs of doors rated to 90 minutes.

Stainless Steel Unit Specifications

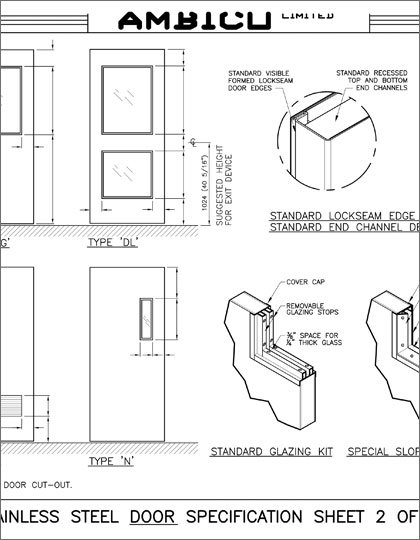

Sample Door Specifications:

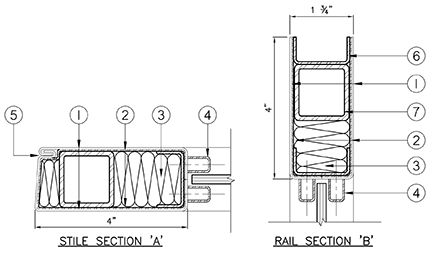

1. Cladding material and finish selection over base door

stiles and rails

2. 18 gauge galvanized steel formed base door stiles and rails

3. Fill all voids with batt insulation

4. Vision lite kit factory installed in door to suit glass thickness

5. Formed visible lockseam door edges

6. Inverted top and bottom end channels

7. Structural tube or channel to frame door and interconnect

stiles and rails for structural stability

Stainless Steel Stile & Rail